On November 11, 2021, Sekisui Chemical Co., Ltd. held an online briefing on solving social issues through its products and technologies. At the briefing session, the "perovskite solar cell" developed by the company was introduced as one of the technologies that "will be the key to realizing a decarbonized society." Keita Kato, the company's president and CEO, said, "The battery has very high expectations.

Perovskite solar cells are solar cells that use a material with a crystalline structure called perovskite. Unlike general silicon-based solar cells, perovskite solar cells can be manufactured by applying the material as if it were printed on a film, making it lightweight and flexible. Realize the characteristics. Due to this characteristic, it is expected to be used in a wide range of places such as building roofs and building walls where the load capacity is limited. Mr. Kato said, "It is extremely lightweight and bendable, so it can be applied to an overwhelmingly large number of areas. It is a battery with very high expectations as it covers a large amount of electricity demand that cannot be covered by conventional silicon solar cells alone." was showing.

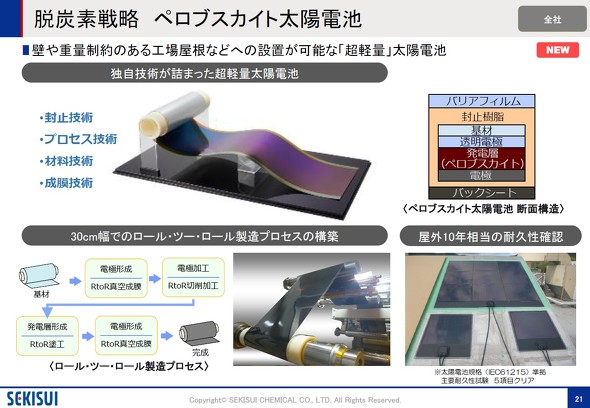

The company has applied its proprietary technologies for encapsulation, processes, materials, and film formation to this perovskite solar cell. The power generation efficiency has achieved 14.3% in July 2021, and Mr. Kato says, "We are aiming for 15% in the future." In addition, Mr. Kato explained, "We have prioritized outdoor durability in development, such as conducting outdoor demonstration tests ahead of other companies." Durability equivalent to 10 years outdoors has been confirmed (cleared 5 main durability tests in accordance with the solar cell standard IEC61215), and in the future, "the goal is to improve (durability) to 15 and 20 years." . Furthermore, regarding the roll-to-roll manufacturing process, after having already established a 30cm-wide manufacturing process, the company said, "We have embarked on the development of a general-purpose 1m-wide manufacturing line for the first time in the industry."

Overview of perovskite solar cells developed by Sekisui Chemical [Click to enlarge] Source: Sekisui Chemical

Overview of perovskite solar cells developed by Sekisui Chemical [Click to enlarge] Source: Sekisui ChemicalExpected applications include walls of buildings, roofs of factories with weight restrictions, and automobiles. Mr. Kato said, "Vehicles are subject to restrictions such as fuel efficiency, so there are great expectations for extremely lightweight perovskite solar cells."

The company has also applied for the Green Innovation Fund project of NEDO (New Energy and Industrial Technology Development Organization) for perovskite solar cells, and will work on development through cooperation between the public and private sectors.

Products that contribute to sustainability for electronics

At the briefing session, efforts by each company were also introduced.

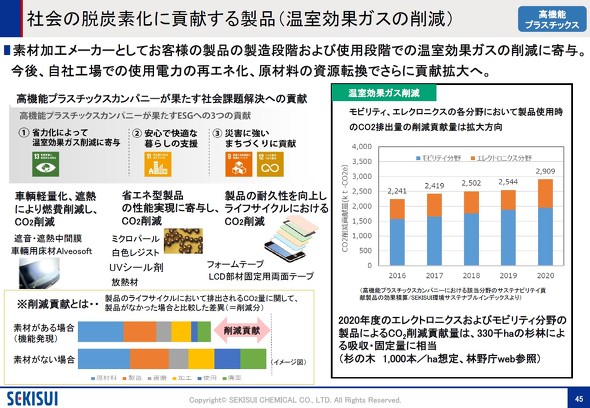

The company's high-performance plastics company, which has the electronics field as one of its strategic fields, has conducted life cycle assessments on the reduction of greenhouse gases, from production to use by users. It is said that it contributes to CO 2 reduction of about 2,900 kilotons . Ikusuke Shimizu, company president, said, "Going forward, we will contribute to the reduction of greenhouse gases more than ever by expanding the possibility of using renewable energy for the electricity used in our factories and by promoting the conversion of raw materials to bioplastics and other resources. I want to," he said.

Greenhouse gas reduction at the High Performance Plastics Company [Click to enlarge] Source: Sekisui Chemical Co., Ltd.

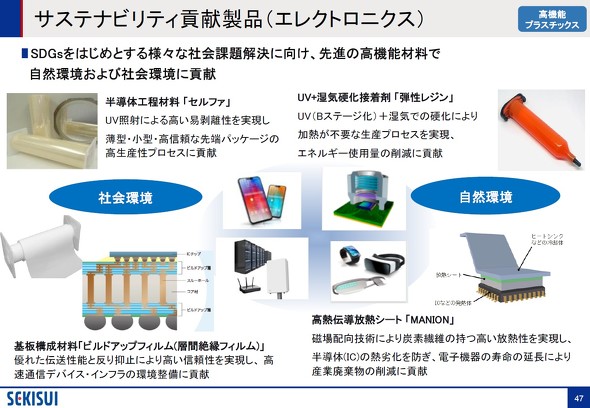

Greenhouse gas reduction at the High Performance Plastics Company [Click to enlarge] Source: Sekisui Chemical Co., Ltd.The products shown in the figure below were introduced as products that contribute to sustainability in the electronics field. In recent years, with the increasing demand for high-speed communication, various IT devices are required to have higher functionality and higher performance. Contribute to the development of social infrastructure. Furthermore, he explained that the "elastic resin" that hardens without heating during use and the heat dissipation sheet that prevents thermal deterioration of electronic devices and extends their life span contribute to the natural environment.

0 コメント:

コメントを投稿